珀金斯Perkins2506-15發動機拆卸組裝手冊

詳細描述

Disassembly and

Assembly

2506-15 Industrial Engine

M G A (Engine)

MGB (Engine)

M G D (Engine)

Table of Contents

Cylinder Head - Remove ...................................... 51

Cylinder Head - Install .......................................... 53

Camshaft - Remove .............................................. 56

Camshaft - Install .................................................. 58

Camshaft Gear - Remove and Install .................. 60

Camshaft Bearings - Remove ............................... 61

Camshaft Bearings - Install ................................... 62

Engine Oil Pan - Remove and Install ................... 64

Cylinder Liner - Remove ....................................... 65

Cylinder Liner - Install ........................................... 66

Piston Cooling Jets - Remove and Install ............. 66

Pistons and Connecting Rods - Remove .............. 67

Pistons and Connecting Rods - Disassemble ....... 68

Pistons and Connecting Rods - Assemble ........... 69

Pistons and Connecting Rods - Install .................. 70

Connecting Rod Bearings - Remove (Connecting

rods in position) ................................................... 71

Connecting Rod Bearings - Install (Connecting rods

in position) ........................................................... 71

Crankshaft Main Bearings - Remove .................... 73

Crankshaft Main Bearings - Install ........................ 74

Crankshaft - Remove ............................................ 75

Crankshaft - Install ................................................ 77

Bearing Clearance - Check ................................... 79

Atmospheric Pressure Sensor - Remove and

Disassembly and Assembly Section

Fuel Priming Pump - Remove and Install ............ 4

Fuel Filter Base - Remove ................................... 4

Fuel Filter Base - Disassemble ............................. 5

Fuel Filter Base - Assemble .................................. 6

Fuel Filter Base - Install ....................................... 6

Fuel Transfer Pump - Remove .............................. 7

Fuel Transfer Pump - Install .................................. 7

Electronic Unit Injector - Remove ......................... 8

Electronic Unit Injector - Install ............................. 9

Electronic Unit Injector Sleeve - Remove ............. 10

Electronic Unit Injector Sleeve - Install ................. 11

Turbocharger - Remove ........................................ 12

Turbocharger - Install ............................................ 13

Exhaust Manifold - Remove and Install ............... 14

Exhaust Elbow - Remove and Install ................... 15

Inlet and Exhaust Valve Springs - Remove and

Install ................................................................... 15

Inlet and Exhaust Valves - Remove and Install .... 17

Inlet and Exhaust Valve Guides - Remove and

Install ................................................................... 19

Engine Oil Filter Base - Remove .......................... 20

Engine Oil Filter Base - Disassemble ................... 21

Engine Oil Filter Base - Assemble ........................ 21

Engine Oil Filter Base - Install .............................. 22

Engine Oil Cooler - Remove ................................. 23

Engine Oil Cooler - Install ..................................... 23

Engine Oil Pump - Remove .................................. 24

Engine Oil Pump - Disassemble ........................... 24

Engine Oil Pump - Assemble ................................ 25

Engine Oil Pump - Install ...................................... 26

Water Pump - Remove ......................................... 27

Water Pump - Install ............................................. 28

Water Temperature Regulator Housing - Remove and

Install .................................................................. 28

Engine Support (Front) - Remove and Install ....... 30

Flywheel - Remove ............................................... 31

Flywheel - Install ................................................... 32

Crankshaft Rear Seal - Remove ........................... 33

Crankshaft Rear Seal - Install ............................... 34

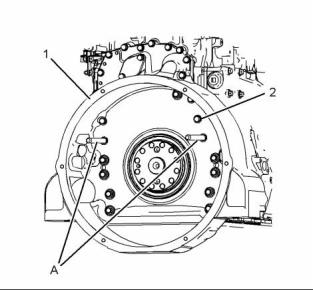

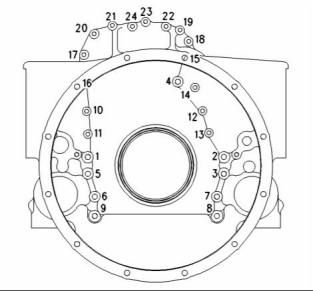

Flywheel Housing - Remove and Install .............. 34

Vibration Damper and Pulley - Remove and Install

............................................................................. 36

Crankshaft Front Seal - Remove .......................... 38

Crankshaft Front Seal - Install .............................. 39

Front Cover - Remove .......................................... 40

Front Cover - Install .............................................. 41

Gear Group (Front) - Remove .............................. 41

Gear Group (Front) - Install .................................. 43

Housing (Front) - Remove .................................... 45

Housing (Front) - Install ........................................ 46

Crankcase Breather - Remove and Install (Open

Breather) ............................................................. 47

Valve Mechanism Cover - Remove and Install ..... 48

Rocker Arm and Shaft - Remove .......................... 49

Rocker Arm - Disassemble ................................... 49

Rocker Arm - Assemble ........................................ 50

Rocker Arm and Shaft - Install .............................. 51

Install ................................................................... 80

Camshaft Position Sensor - Remove and Install .. 81

Crankshaft Position Sensor - Remove and

Install ................................................................... 82

Coolant Temperature Sensor - Remove and

Install ................................................................... 83

Engine Oil Pressure Sensor - Remove and Install

............................................................................. 84

Fuel Temperature Sensor - Remove and Install ... 85

Inlet Manifold Temperature Sensor - Remove and

Install ................................................................... 86

Inlet Manifold Pressure Sensor - Remove and

Install ................................................................... 87

Belt Tightener - Remove ....................................... 88

Belt Tightener - Install ........................................... 89

Fan - Remove and Install ..................................... 89

Fan Drive - Remove ............................................. 90

Fan Drive - Install .................................................. 91

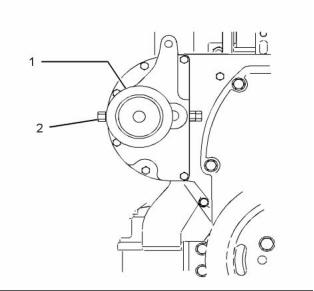

Pump Drive - Remove (Transfer pump) ................ 91

Pump Drive - Disassemble (Transfer pump) ......... 92

Pump Drive - Assemble (Transfer pump) ............. 93

Pump Drive - Install (Transfer pump) .................... 93

Electronic Control Module - Remove and Install ... 94

Alternator - Remove and Install ........................... 95

Electric Starting Motor - Remove and Install ....... 96

Index Section

Index ..................................................................... 97

This document has been printed from SPI². Not for Resale

![]()

4

KENR6232

Disassembly and Assembly Section

Disassembly and Assembly

Section

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

i02554756

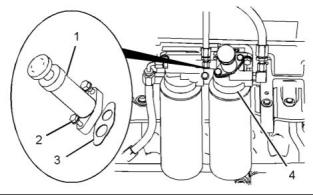

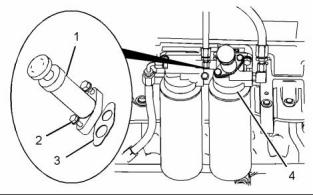

Fuel Priming Pump - Remove

and Install

Contaminants may cause rapid wear and shortened

component life.

Removal Procedure

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

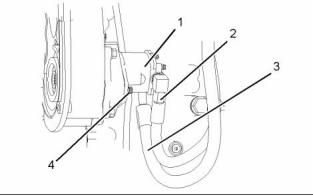

g01279497

Dispose of all fluids according to local regulations and

mandates.

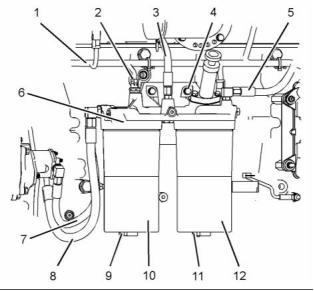

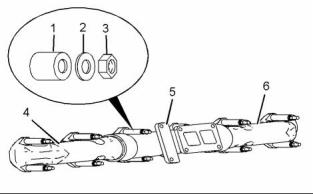

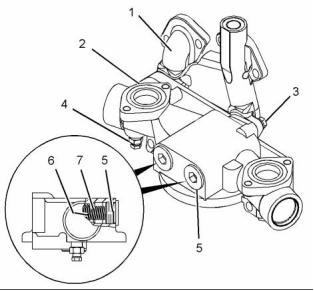

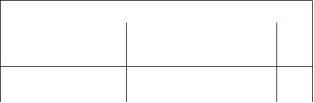

Illustration 2

1. Position a new joint (3) on fuel filter base (4).

Note: Ensure correct orientation of the joint.

NOTICE

Keep all parts clean from contaminants.

2. Position the fuel priming pump assembly (1) on

the fuel filter base and install bolts (2). Tighten the

1/4" bolt to a torque of 12 N·m (105 lb in). Tighten

the 5/16" bolt to a torque of 25 N·m (221 lb in).

Contaminants may cause rapid wear and shortened

component life.

1. Turn the fuel supply to the “OFF” position.

3. Turn the fuel supply to the “ON” position.

4. Remove the air from the system. Refer to Systems

Operation, Testing and Adjusting, “Fuel System -

Prime”.

i02554755

Fuel Filter Base - Remove

Removal Procedure

NOTICE

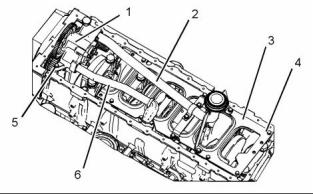

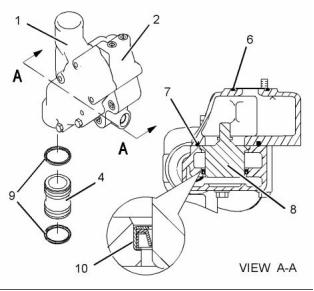

g01279497

Illustration 1

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

2. Remove bolts (2). Remove fuel priming pump

assembly (1) from fuel filter base (4).

3. Remove joint (3) from the fuel priming pump

assembly and the fuel filter base.

Dispose of all fluids according to local regulations and

mandates.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

5

Disassembly and Assembly Section

i02554753

Fuel Filter Base - Disassemble

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Disassembly Procedure

1. Turn the fuel supply to the “OFF” position.

Start By:

a. Remove the fuel filter base. Refer to Disassembly

and Assembly, “Fuel Filter Base - Remove”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

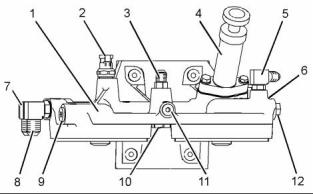

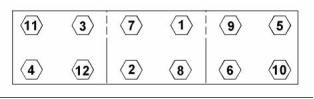

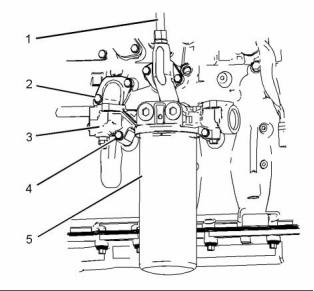

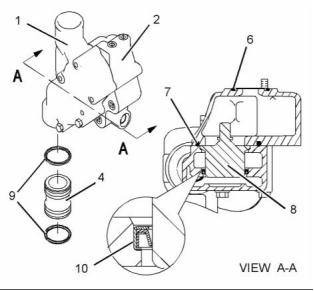

g01279811

Illustration 3

2. Place a suitable container below the fuel filter

base in order to drain the fuel from the fuel filter

assemblies (10) and (12).

g01279898

Illustration 4

1. Remove fuel priming pump (4) from fuel filter

base assembly (1). Refer to Disassembly and

Assembly, “Fuel Priming Pump - Remove and

Install”.

3. Remove plugs (9) and (11). Allow the fuel to drain.

4. Disconnect harness assembly (1) from fuel

temperature sensor (2).

2. Remove fuel temperature sensor (2) from fuel

filter base assembly (1). Refer to Disassembly and

Assembly, “Fuel Temperature Sensor - Remove

and Install”.

Note: In order to disconnect the harness assembly,

slide the locking tab into the unlocked position.

5. Disconnect hose assembly (3). Disconnect hose

assembly (5). Disconnect hose assemblies (7)

and (8). Plug the open hose assemblies.

3. Remove fuel bypass valve (6) from fuel filter base

assembly (1). Remove the O-ring seals from the

fuel bypass valve.

6. Use a suitable tool with a 1/2" square drive

in order to remove fuel filter assemblies (10)

and (12). Remove the O-ring seals. Remove

the fuel filter elements. Refer to Operation and

Maintenance Manual, “Fuel Filter - Replace” for

more information.

4. Remove fuel check valve (10) from fuel filter base

assembly (1). Remove the O-ring seals from the

fuel check valve.

5. Remove connections (3), (5), (7) and (8) from fuel

filter base assembly (1). Remove the O-ring seals

from the connections.

7. Remove bolts (4). Remove fuel filter base (6).

6. Remove plugs (9), (11) and (12) from fuel filter

base assembly (1). Remove the O-ring seals from

the plugs.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

6

KENR6232

Disassembly and Assembly Section

i02554752

Fuel Filter Base - Assemble

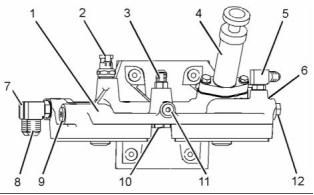

6. Install fuel temperature sensor (2) to fuel filter

base assembly (1). Refer to Disassembly and

Assembly, “Fuel Temperature Sensor - Remove

and Install”.

7. Install fuel priming pump (4) to fuel filter

base assembly (1). Refer to Disassembly and

Assembly, “Fuel Priming Pump - Remove and

Install”.

Assembly Procedure

NOTICE

Keep all parts clean from contaminants.

End By:

Contaminants may cause rapid wear and shortened

component life.

a. Install the fuel filter base. Refer to Disassembly

and Assembly, “Fuel Filter Base - Install”.

1. Ensure that the filter base is clean and free from

i02554754

damage. If necessary, replace the filter base.

Fuel Filter Base - Install

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

g01279898

Illustration 5

2. Install new O-ring seals to plugs (9), (11) and (12).

Install the plugs to fuel filter base assembly (1).

Tighten plug (9) to a torque of 41 N·m (30 lb ft).

Tighten plugs (11) and (12) to a torque of 15 N·m

(11 lb ft).

3. Install new O-ring seals to connections (3), (5), (7)

and (8). Install the connections to fuel filter base

assembly (1). Tighten connections (3), (5) and (7)

to a torque of 15 N·m (11 lb ft). Tighten connection

(8) to a torque of 41 N·m (30 lb ft).

Note: Ensure correct orientation of the connections.

4. Install new O-ring seals to fuel bypass valve (6).

Install the fuel bypass valve to fuel filter base

assembly (1). Tighten fuel bypass valve (6) to a

torque of 35 N·m (26 lb ft).

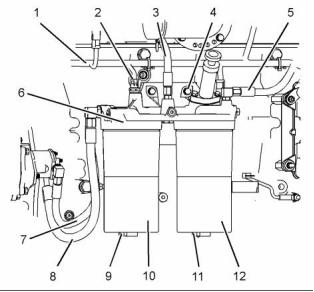

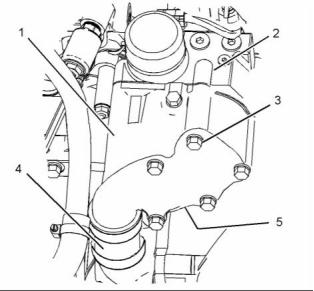

g01279811

Illustration 6

1. Position fuel filter base (6) and install bolts (4).

5. Install new O-ring seals to fuel check valve (10).

Install the fuel check valve in fuel filter base

assembly (1). Tighten the fuel check valve to a

torque of 35 N·m (26 lb ft).

Tighten the bolts to a torque of 47 N·m (35 lb ft).

2. Install new O-ring seals and new fuel filter

elements to fuel filter assemblies (10) and (12).

Use a suitable tool with a 1/2" square drive in

order to install the fuel filter assemblies.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

7

Disassembly and Assembly Section

Install new O-ring seals to plugs (9) and (11).

Install the plugs to fuel filter assemblies (10) and

(12).

Refer to Operation and Maintenance Manual,

“Fuel Filter - Replace” for more information.

3. Connect hose assemblies (3), (5), (7) and (8).

4. Connect harness assembly (1) to fuel temperature

sensor (2). Slide the locking tab into the locked

position.

5. Turn the fuel supply to the “ON” position.

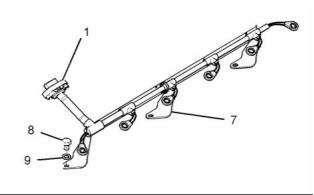

g01280901

6. Remove the air from the system. Refer to Systems

Operation, Testing and Adjusting, “Fuel System -

Prime”.

Illustration 7

3. Disconnect hose assemblies (2) and (3) from fuel

transfer pump (1). Plug the open hose assemblies.

4. Remove bolts (4) and remove fuel transfer pump

i02554761

Fuel Transfer Pump - Remove

(1).

5. Remove the O-ring seal from fuel transfer pump

(1).

Removal Procedure

i02554849

NOTICE

Fuel Transfer Pump - Install

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Dispose of all fluids according to local regulations and

mandates.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Keep all parts clean from contaminants.

1. Ensure that the fuel transfer pump is clean and

free from damage.

Contaminants may cause rapid wear and shortened

component life.

1. Turn the fuel supply to the “OFF” position.

2. Place a suitable container below the fuel transfer

pump in order to catch any fuel that might be

spilled.

g01280943

Illustration 8

2. Lubricate a new O-ring seal with clean engine oil.

Install the O-ring seal to fuel transfer pump (1).

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

8

KENR6232

Disassembly and Assembly Section

3. Position fuel transfer pump (1) on pump drive (5).

Note: Ensure that the splines on the shaft of the fuel

transfer pump are correctly engaged into the pump

drive.

4. Install bolts (4). Tighten the bolts to a torque of

47 N·m (35 lb ft).

5. Remove the plugs from the hose assemblies.

Connect hose assemblies (2) and (3) to fuel

transfer pump (1).

6. Turn the fuel supply to the “ON” position.

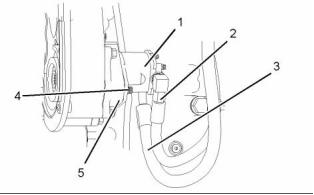

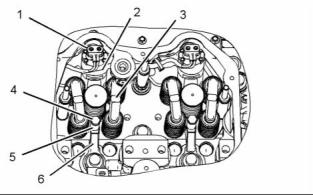

g01150587

7. Remove the air from the fuel system. Refer to

Systems Operation, Testing and Adjusting, “Fuel

System - Prime”.

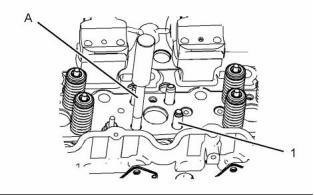

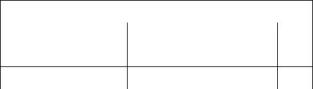

Illustration 9

2. Disconnect harness assembly (1) from electronic

unit injector (2).

3. Remove valve bridges (3).

i02554720

Electronic Unit Injector -

Remove

NOTICE

If the injector hold down bolt is loose during the re-

moval procedure, inspect the injector bore for wear

and debris. Replace the clamp and spacer.

Removal Procedure

Table 1

Required Tools

Tool

Part Number

Part Description

Pry Bar

Qty

A

27610288

1

Start By:

a. Remove the rocker arms and the rocker arm shaft.

Refer to Disassembly and Assembly, “Rocker Arm

and Shaft - Remove”.

g01284035

Illustration 10

NOTICE

Keep all parts clean from contaminants.

4. Remove bolts (8) and washers (9). Remove

harness assembly (1) and support bracket (7) as

a unit.

Contaminants may cause rapid wear and shortened

component life.

5. Remove bolt (4) and spacer (5).

1. Turn the fuel supply to the OFF position.

6. Place an identification mark on electronic unit

injector (2) for installation purposes. Each

electronic unit injector must be reinstalled in the

original location in the cylinder head.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

9

Disassembly and Assembly Section

i02554719

Electronic Unit Injector - Install

Installation Procedure

Table 2

Required Tools

Tool

Part

Part Description

Qty

Number

GE50028

GE50046

Vacuum Pump

1

1

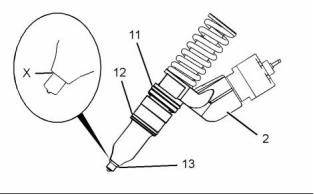

g01073439

Illustration 11

Fluid Sampling Bottle

B

Tube

7. Use Tooling (A) to pry beneath the base and free

GE50030

-

1

1

1

1

7.9 mm (0.31 inch) OD

electronic unit injector (2).

C

D

E

Large Bore Brush

8. Remove electronic unit injector (2) and clamp (6)

Surface Reconditioning

Pad

from the cylinder head.

27610308

27610296

Torque Wrench

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Use Tooling (D) to clean the carbon deposit from

the inside of the electronic unit injector sleeve.

2. Use Tooling (B) to remove the fuel and oil from

the cylinder. Evacuate as much fuel and oil as

possible from the cylinder before installing the

electronic unit injector. Several evacuations may

be necessary.

g01284341

Illustration 12

9. Remove O-ring seals (11) and (12) from electronic

unit injector (2).

g01284074

Illustration 13

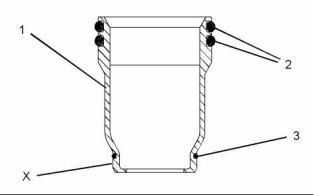

3. Ensure that seat area (X) on the electronic unit

injector is clean and free carbon.

4. Install new O-ring seals (11) and (12) on the

electronic unit injector. Lubricate the O-ring seals

with clean engine oil.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

10

KENR6232

Disassembly and Assembly Section

5. Install a new O-ring seal (13) on the electronic unit

Note: Ensure that used valve bridges are reinstalled

in the original location and the original orientation.

Do not interchange the location or the orientation of

used valve bridges.

injector.

Note: O-ring seal (13) should be installed dry.

11. Install the rocker arms and the rocker arm shaft.

Refer to Disassembly and Assembly, “Rocker Arm

and Shaft - Install”.

NOTICE

If a replacement electronic unit injector is installed, the

calibration code must be programmed into the elec-

tronic control module. Refer to Troubleshooting Guide,

“Injector Trim File” for more information.

12. Turn the fuel supply to the “ON” position.

13. Remove the air from the fuel system. Refer to

Systems Operation, Testing and Adjusting, “Fuel

System - Prime”.

i02554722

Electronic Unit Injector Sleeve

- Remove

Removal Procedure

Table 3

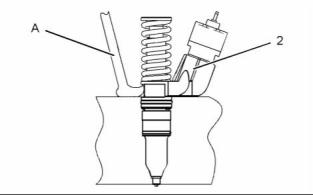

g01150587

Illustration 14

Required Tools

6. Install clamp (6) to electronic unit injector (2).

Install electronic unit injector (2) into the original

location in the cylinder head.

Tool

Part Number

Part Description

Qty

A

GE50021

Injector Sleeve Tool

1

7. Install spacer (5) and bolt (4). Tighten bolt (4) to a

Start By:

torque of 55 N·m (41 lb ft).

a. Remove the electronic unit injectors. Refer to

Disassembly and Assembly, “Electronic Unit

Injector - Remove”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Drain the coolant from the engine. Refer to

Operation and Maintenance Manual, “Cooling

System Coolant - Change”.

g01284035

Illustration 15

8. Install harness assembly (1) and support bracket

(7) as a unit. Install bolts (8) and washers (9).

Tighten bolts (8) to a torque of 105 N·m (77 lb ft).

9. Connect harness assembly (1) to electronic unit

injector (2). Use Tooling (E) to tighten the nuts to a

torque of 2.5 N·m (22 lb in).

10. Install bridge assemblies (3) in the respective

locations.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

11

Disassembly and Assembly Section

NOTICE

Ensure that the electronic unit injector sleeve and the

cylinder head bore are completely free of oil, dirt, and

sealant debris.

g01076133

Illustration 16

2. Install Tooling (A) in electronic unit injector sleeve

(1).

3. Tighten the nut on Tooling (A) until the electronic

unit injector sleeve is pulled free of the cylinder

head.

g01043165

Illustration 17

2. Install new O-ring seals (2) and (3) to electronic

unit injector sleeve (1).

4. Remove O-ring seals (2) and O-ring seal (3) from

electronic unit injector sleeve (1).

Note: Do not apply Tooling (C) to the cylinder head

surfaces. Apply Tooling (C) to the electronic unit

injector sleeve only.

i02554721

Electronic Unit Injector Sleeve

- Install

3. Apply a small continuous bead of Tooling (C) to

surface (X) of electronic unit injector sleeve (1).

4. Lubricate O-ring seals (2) with clean engine oil.

5. Position Tooling (A) and the electronic unit injector

sleeve in the cylinder head. Use care not to

damage the O-ring seals on the electronic unit

injector sleeve.

Installation Procedure

Table 4

Required Tools

6. Use Tooling (A) to install electronic unit injector

Tool

Part Number

GE50021

GE50023

GE50024

GE50022

CV60893

Part Description

Injector Sleeve Tool

Tapered Brush

Qty

1

sleeve (1) in the cylinder head.

A

Note: Ensure that the electronic unit injector sleeve

1

is properly seated in the cylinder head.

B

C

Small Bore Brush

End Brush

1

7. Remove Tooling (A). Use a clean towel and

1

remove excess Tooling (C).

Retaining Compound

1

8. Fill the cooling system with coolant. Refer to

Operation and Maintenance, “Refill Capacities” for

the cooling system capacity.

NOTICE

Keep all parts clean from contaminants.

End By:

Contaminants may cause rapid wear and shortened

component life.

a. Install the electronic unit injectors. Refer to

Disassembly and Assembly, “Electronic Unit

Injector - Install”.

1. Use Tooling (B) to clean the bore in the cylinder

head for the electronic unit injector sleeve.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

12

KENR6232

Disassembly and Assembly Section

i02554785

Turbocharger - Remove

Removal Procedure

Start By:

a. Remove the exhaust elbow. Refer to Disassembly

and Assembly, “Exhaust Elbow - Remove and

Install”.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to local regulations and

mandates.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Disconnect the air hoses for the turbocharger inlet

and for the turbocharger outlet.

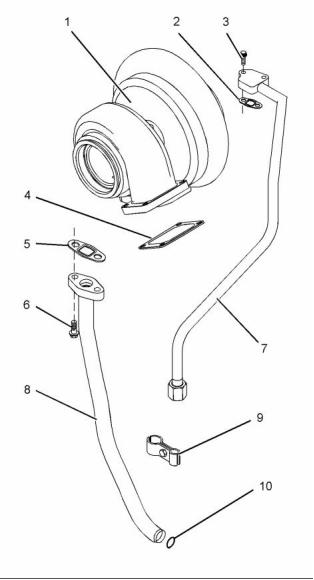

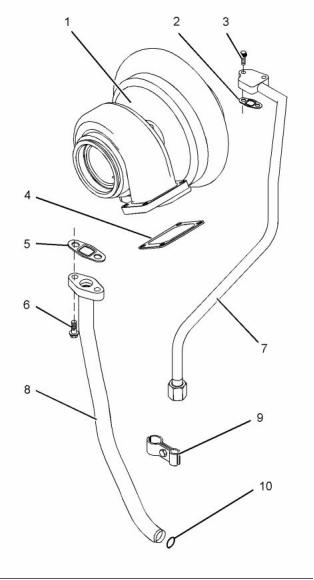

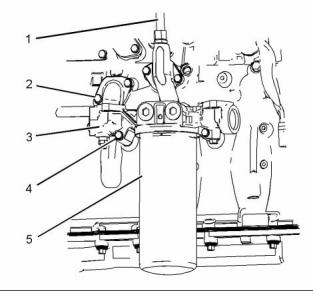

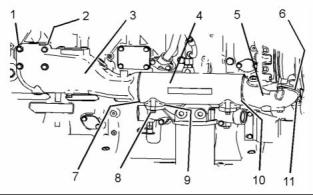

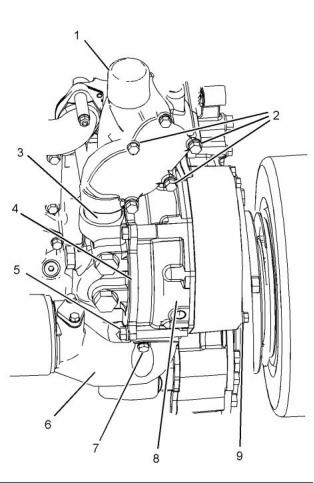

g01283022

Illustration 18

2. Follow Steps 2.a through 2.c in order to remove

the tube assembly (7) for the oil feed.

a. Remove tube clamp (9) that secures tube

assembly (7) to tube assembly (8). Note the

position of the clamp.

b. Disconnect tube assembly (7) from the engine

oil filter base.

c. Remove bolts (3). Remove tube assembly (7)

and joint (2) from turbocharger (1).

3. Follow Steps 3 through 3.c in order to remove the

tube assembly (8) for the oil drain.

a. Remove bolts (6).

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

13

Disassembly and Assembly Section

b. Remove tube assembly (8) and joint (5).

c. Remove O-ring seal (10) from tube assembly

(8).

4. Attach a suitable lifting device to turbocharger (1).

The weight of the turbocharger is approximately

30 kg (66 lb).

5. Remove the fasteners for the turbocharger. Use

the lifting device to remove turbocharger (1) from

the exhaust manifold. Remove gasket (4).

i02554784

Turbocharger - Install

Installation Procedure

Table 5

Required Tools

Tool

Part

Part Description

Qty

Number

A

CV60889

Anti-Seize Compound

1

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

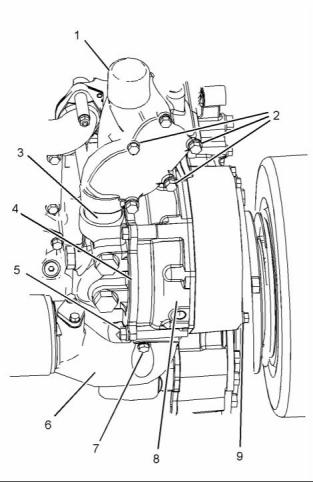

g01283022

Illustration 19

1. Clean the mating surfaces of the exhaust manifold.

Position a new gasket (4) on the exhaust manifold.

2. Attach a suitable lifting device to turbocharger

(1). The weight of turbocharger is approximately

30 kg (66 lb). Use the lifting device to install

turbocharger (1) onto the exhaust manifold.

3. Apply Tooling (A) to the threads of the exhaust

manifold bolts. Install the bolts and install locknuts

finger tight.

4. Install a new O-ring seal (10) to tube assembly

(8). Install tube assembly (7) and new joint (5).

Install bolts (6) finger tight.

5. Install tube assembly (7) and a new joint (2).

Install bolts (3) finger tight. Connect the lower end

of tube assembly (7) to the engine oil filter base.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

14

KENR6232

Disassembly and Assembly Section

6. Install tube clamp (9) to tube assembly (7) to tube

5. If necessary, remove the taperlock studs from the

assembly (8).

cylinder head.

Note: Ensure that the clamp is installed in the correct

Installation Procedure

position.

Table 6

7. Tighten the fasteners for the turbocharger to a

Required Tools

torque of 55 N·m (41 lb ft).

Tool

Part Number

Part Description

Qty

-

8. Tighten the bolts for tube assemblies (7) and (8)

A

CV60889

Anti-Seize Compound

to a torque of 47 N·m (35 lb ft).

9. Connect the air hoses for the turbocharger inlet

NOTICE

and for the turbocharger outlet.

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

i02554739

Exhaust Manifold - Remove

and Install

1. Install the taperlock studs in the cylinder head and

tighten to a torque of 35 N·m (26 lb ft).

Removal Procedure

Start By:

a. Remove the turbocharger. Refer to Disassembly

and Assembly, “Turbocharger - Remove”.

b. Remove the water temperature regulator housing.

Refer to Disassembly and Assembly, “Water

Temperature Regulator Housing - Remove and

Install”.

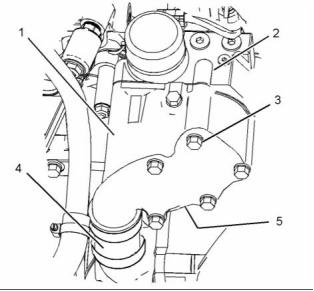

g01283599

Illustration 21

2. Assemble exhaust manifolds (4), (5) and (6).

3. Install the exhaust manifold gaskets onto the

taperlock studs.

4. Install the assembly of the exhaust manifolds on

the taperlock studs.

Note: Ensure that the holes in exhaust manifolds are

centralized with the taperlock studs.

g01283599

5. Apply Tooling (A) to the threads of the taperlock

studs. Install spacers (1), washers (2) and

locknuts (3).

Illustration 20

1. Remove locknuts (3), washers (2) and spacers (1).

2. Remove exhaust manifolds (4), (5) and (6).

Note: Remove manifolds as one assembly.

3. Remove the exhaust manifold gaskets.

4. Remove exhaust manifolds (4) and (6) from

exhaust manifold (5).

g01100255

Illustration 22

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

15

Disassembly and Assembly Section

6. Tighten the locknuts in a numerical sequence that

is shown in Illustration 22. Tighten the locknuts to

a torque of 38 N·m (28 lb ft).

Installation Procedures

NOTICE

Keep all parts clean from contaminants.

End By:

Contaminants may cause rapid wear and shortened

component life.

a. Install the water temperature regulator housing.

Refer to Disassembly and Assembly, “Water

Temperature Regulator Housing - Remove and

Install”.

b. Install the turbocharger. Refer to Disassembly and

Assembly, “Turbocharger - Install”.

i02554738

Exhaust Elbow - Remove and

Install

Removal Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

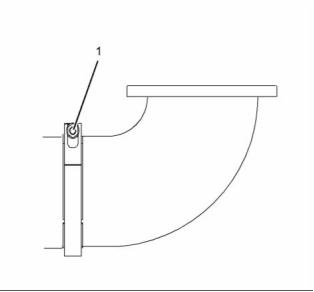

g01296103

Illustration 24

1. Thoroughly clean the exhaust elbow and the outlet

of the turbocharger. Inspect the components for

wear or damage. Replace any components that

are worn or damaged.

2. Position clamp (1) and install the exhaust elbow

to the turbocharger. Ensure correct orientation of

the band clamp.

3. Tighten the allen head bolt to a torque of 13.5 N·m

(10 lb ft).

i02554768

Inlet and Exhaust Valve

Springs - Remove and Install

Removal Procedure

g01296103

Illustration 23

1. Use an allen wrench in order to loosen clamp (1)

Table 7

that secures the exhaust elbow.

Required Tools

Tool

A

Part Number

CH11148

Part Description

Engine Turning Tool

Qty

1

2. Remove the exhaust elbow and the clamp from

the turbocharger.

B

GE50026

Valve Spring Compressor

1

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

16

KENR6232

Disassembly and Assembly Section

Start By:

a. Remove the electronic unit injectors. Refer to

Disassembly and Assembly, “Electronic Unit

Injector - Remove”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The following procedure should be adopted in

order to remove the valve springs when the cylinder

head is installed to the engine. Refer to Disassembly

and Assembly Manual, “Inlet and Exhaust Valves -

Remove and Install” for the procedure to remove the

valve springs from a cylinder head that has been

removed from the engine.

1. Use Tooling (A) to position the appropriate piston

at the top center position before the valve spring

is removed.

g01284821

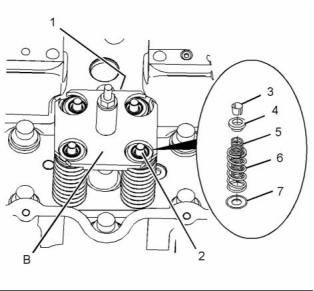

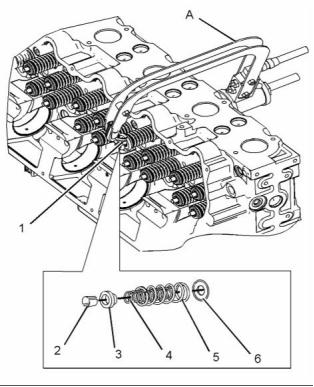

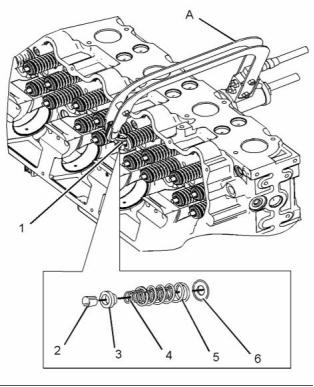

Illustration 26

Note: Failure to ensure that the piston is at the top

center position may allow the valve to drop into the

cylinder bore.

Personal injury can result from being struck by

parts propelled by a released spring force.

Make sure to wear all necessary protective equip-

ment.

NOTICE

Do not turn the crankshaft while the valve springs are

removed.

Follow the recommended procedure and use all

recommended tooling to release the spring force.

Note: Valve springs must be replaced in pairs for the

inlet valves or the exhaust valves of each cylinder. If

all valve springs require replacement the procedure

can be carried out on two cylinders at the same time.

The procedure can be carried out on the following

pairs of cylinders. 1 with 6, 2 with 5, and 3 with 4.

Ensure that all of the valve springs are installed

before changing from one pair of cylinders to another

pair of cylinders.

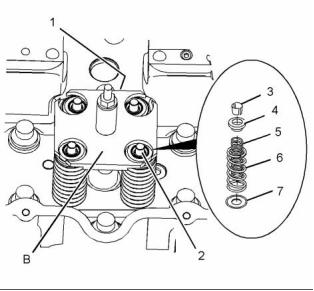

2. Install Tooling (B) in the electronic unit injector

sleeve. Secure Tooling (B) with unit injector clamp

(1).

3. Tighten the nut until valve keepers (3) are loose

on valves (2).

4. Remove valve keepers (3).

5. Loosen the nut in order to release the pressure

on Tooling (B). Remove unit injector clamp (1).

Carefully remove Tooling (B).

6. Remove valve rotators (4).

7. Remove outer valve springs (6) and inner valve

g01284804

springs (5).

Illustration 25

8. Remove washers (7) from the valve guide.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

17

Disassembly and Assembly Section

Installation Procedure

Table 8

The valve spring keepers can be thrown from

the valve when the valve spring compressor is

released. Ensure that the valve spring keepers

are properly installed on the valve stem. To help

prevent personal injury, keep away from the front

of the valve spring keepers and &, nbsp;valve springs

during the installation of the valves.

Required Tools

Tool

Part Number

Part Description

Qty

B

GE50026

Valve Spring Compressor

1

NOTICE

Keep all parts clean from contaminants.

6. Use Tooling (B) to compress the valve springs.

Contaminants may cause rapid wear and shortened

component life.

Install valve keepers (3).

7. Loosen the nut in order to release the pressure

on Tooling (B). Remove unit injector clamp (1).

Carefully remove Tooling (B).

1. Inspect the valve springs for damage and for the

correct length. Refer to Specifications Manual,

“Cylinder Head Valves ”.

8. Lightly strike the top of the valve with a soft faced

hammer in order to ensure that valve keepers (2)

are properly installed.

2. Lubricate the valve stems with clean engine oil.

End By:

a. Install the electronic unit injectors. Refer to

Disassembly and Assembly, “Electronic Unit

Injector - Install”.

i02554769

Inlet and Exhaust Valves -

Remove and Install

Removal Procedure

Table 9

Required Tools

Tool

Part Number

Part Description

Qty

g01284821

Illustration 27

Valve Spring

Compressor

A

-

1

Start By:

Improper assembly of parts that are spring loaded

can cause bodily injury.

a. Remove the cylinder head. Refer to Disassembly

and Assembly, “Cylinder Head - Remove”.

To prevent possible injury, follow the established

assembly procedure and wear protective equip-

ment.

NOTICE

Keep all parts clean from contaminants.

3. Install washers (7).

Contaminants may cause rapid wear and shortened

component life.

4. Install inner valve springs (5) and outer valve

springs (6).

5. Position valve rotators (4) on the valve springs.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

18

KENR6232

Disassembly and Assembly Section

Installation Procedure

Table 10

Required Tools

Tool

A

Part Number

Part Description

Qty

1

Valve Spring

Compressor

-

B

GE50027

Seal Installer

1

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Inspect the valve springs for damage and for the

correct length. Refer to Specifications Manual,

“Cylinder Head Valves ”.

Note: Valve springs must be replaced in pairs for the

inlet valve or the exhaust valve of each cylinder.

2. Inspect the valves. Refer to Specifications,

“Cylinder Head Valves” for additional information

on the inlet and exhaust valves.

g01015263

Illustration 28

3. Use Tooling (B) in order to install new valve stem

seals onto the valve guides.

Note: The outer face of the valve guide must be

Personal injury can result from being struck by

parts propelled by a released spring force.

clean and dry before installing the valve stem seal.

4. Lubricate the valves with clean engine oil. Install

Make sure to wear all necessary protective equip-

ment.

the valves in the cylinder head.

Follow the recommended procedure and use all

recommended tooling to release the spring force.

1. Install Tooling (A) and compress the valve springs.

Remove valve keepers (2) from valve (1).

2. Carefully remove Tooling (A) from valve (1).

3. Remove valve rotator (3).

4. Remove outer valve spring (5) and inner valve

spring (4) from valve (1).

5. Remove washer (6) and valve (1) from the valve

guide.

6. Remove the valve stem seal.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

19

Disassembly and Assembly Section

9. Carefully remove Tooling (A). Lightly strike the top

of the valve with a soft faced hammer in order

to ensure that valve keepers (2) are properly

installed.

End By:

a. Install the cylinder head. Refer to Disassembly

and Assembly, “Cylinder Head - Install”.

i02554766

Inlet and Exhaust Valve Guides

- Remove and Install

Removal Procedure

Table 11

Required Tools

Tool

Part Number

Part Description

Qty

A

GE50043

Valve Guide Tool

1

Start By:

g01015263

Illustration 29

a. Remove the inlet and exhaust valves. Refer to

Disassembly and Assembly, “Inlet and Exhaust

Valves - Remove and Install”.

Improper assembly of parts that are spring loaded

can cause bodily injury.

NOTICE

Keep all parts clean from contaminants.

To prevent possible injury, follow the established

assembly procedure and wear protective equip-

ment.

Contaminants may cause rapid wear and shortened

component life.

5. Install washer (6).

6. Install inner valve spring (4) and outer valve spring

(5).

7. Position valve rotator (3) on the valve springs.

8. Use Tooling (A) to compress valve springs. Install

valve keepers (2) .

The valve spring keepers can be thrown from

the valve when the valve spring compressor is

released. Ensure that the valve spring keepers

are properly installed on the valve stem. To help

prevent personal injury, keep away from the front

of the valve spring keepers and valve springs

during the installation of the valves.

g01289154

Illustration 30

1. Use Tooling (A) and a hammer to remove valve

guide (1) from the cylinder head.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

20

KENR6232

Disassembly and Assembly Section

Installation Procedure

i02554729

Engine Oil Filter Base -

Remove

Table 12

Required Tools

Tool

A

Part Number

GE50043

Part Description

Valve Guide Tool

Qty

1

Removal Procedure

B

GE50044

Valve Guide Sleeve

1

Start By:

NOTICE

Keep all parts clean from contaminants.

a. Remove the oil cooler. Refer to Disassembly and

Assembly, “Engine Oil Cooler - Remove”.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to local regulations and

mandates.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

g01289167

Illustration 31

1. Lubricate the bores for the valve guides with clean

engine oil.

2. Install valve guide (1) in the cylinder head with

Tooling (A) and Tooling (B).

Note: Tooling (B) must be used in order to install the

valve guide to the correct height.

Height to top of valve guide from cylinder head

surface ..... 35.00 ± 0.50 mm (1.378 ± 0.020 inch)

Note: For more information, refer to Specifications,

“Cylinder Head Valves”.

End By:

a. Install the inlet and exhaust valves. Refer to

Disassembly and Assembly, “Inlet and Exhaust

Valves - Remove and Install”.

g01282258

Illustration 32

1. Use a suitable tool with a 1/2" square drive in

order to remove engine oil filter (5). Remove the

O-ring seal. Remove the filter element. Refer to

Operation and Maintenance Manual, “Engine Oil

- Change” for more information.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

21

Disassembly and Assembly Section

2. Disconnect tube assembly (1).

3. Remove bolts (2) and bolts (4).

4. Remove engine oil filter base (3). Remove the

O-ring seals from the engine oil filter base.

i02554727

Engine Oil Filter Base -

Disassemble

Disassembly Procedure

Start By:

a. Remove the engine oil filter base. Refer to

Disassembly and Assembly, “Engine Oil Filter

Base - Remove”.

g01282540

Illustration 33

1. Remove bolts (3). Remove elbow (1) from engine

oil filter base (2). Remove the O-ring seals from

the elbow.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

2. Remove plug (5). Remove the O-ring seal from

plug (5).

3. Remove spring (7).

4. Remove plunger (6).

Personal injury can result from being struck by

parts propelled by a released spring force.

5. If necessary, remove oil sampling valve (4) from

the engine oil filter base. remove the O-ring seal

from the oil sampling valve.

Make sure to wear all necessary protective equip-

ment.

Follow the recommended procedure and use all

recommended tooling to release the spring force.

i02554726

Engine Oil Filter Base -

Assemble

Assembly Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

22

KENR6232

Disassembly and Assembly Section

i02554728

Engine Oil Filter Base - Install

Improper assembly of parts that are spring loaded

can cause bodily injury.

To prevent possible injury, follow the established

assembly procedure and wear protective equip-

ment.

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

g01282540

Illustration 34

1. Inspect the components for wear or damage.

Replace any components that are worn or

damaged.

g01282258

Illustration 35

2. Lubricate plunger (6) and spring (7) with clean

engine oil. Install the plunger and the spring into

engine oil filter base (2).

1. Install new O-ring seals to engine oil filter base (3).

2. Position engine oil filter base (3) on the engine

and install bolts (2) and bolts (4). Tighten the bolts

to a torque of 47 N·m (35 lb ft).

3. Install a new O-ring seal to plug (5). Install plug (5)

to engine oil filter base (2). Tighten plug (5) to a

torque of 100 N·m (74 lb ft).

3. Connect tube assembly (1).

4. Install new O-ring seals to elbow (1). Position

elbow (1) on the engine oil filter base and install

bolts (3).

4. Install the oil cooler. Refer to Disassembly and

Assembly, “Engine Oil Cooler - Install”.

5. If necessary, install a new O-ring seal to oil

sampling valve (4). Install oil sampling valve (4) to

engine oil filter base (2). Tighten the oil sampling

valve to a torque of 24 N·m (18 lb ft).

5. Install a new O-ring seal to engine oil filter (5).

Install engine oil filter (5) to engine oil filter base

(3). Refer to Operation and Maintenance Manual,

“Engine Oil - Change” for more information.

End By:

a. Install the engine oil filter base. Refer to

Disassembly and Assembly, “Engine Oil Filter

Base - Install”.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

23

Disassembly and Assembly Section

i02554725

Engine Oil Cooler - Remove

i02554723

Engine Oil Cooler - Install

Removal Procedure

Installation Procedure

Table 13

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Required Tools

Part

Tool

Number

Part Description

Qty

POWERPART

A

21820221

-

Rubber Grease

Dispose of all fluids according to local regulations and

mandates.

NOTICE

Keep all parts clean from contaminants.

1. Drain the coolant from the cooling system into

a suitable container for storage or for disposal.

Refer to Operation and Maintenance Manual,

“Cooling System Coolant - Change”.

Contaminants may cause rapid wear and shortened

component life.

g01282186

Illustration 37

g01282186

Illustration 36

1. Install a new O-ring seal (10) to oil cooler bonnet

(5). Apply Tooling (A) to the O-ring seal. Install

joint (6) to oil cooler bonnet (5). Position the oil

cooler bonnet on the water pump and install bolts

(11). Tighten the bolts finger tight.

2. Remove bolts (1). Remove outlet bonnet (3) from

the cylinder block and from the engine oil cooler.

Remove joint (2) and O-ring seal (7) from the

outlet bonnet.

2. Install two new O-ring seals (9) to the engine oil

3. Remove bolts (8). Rotate core assembly (4) and

slide the core assembly toward the rear of the

engine in order to remove the core assembly from

the engine oil filter base. Remove O-ring seals (9)

from the engine oil filter base.

filter base.

3. Slide core assembly (4) toward the front of the

engine. Rotate the core assembly into position.

Install bolts (8). Tighten the bolts finger tight.

4. Remove bolts (11). Remove oil cooler bonnet (5)

from the water pump. Remove joint (6) and O-ring

seal (10) from the oil cooler bonnet.

4. Install a new O-ring seal (7) to outlet bonnet (3).

Apply Tooling (A) to the O-ring seal. Install joint (2)

to outlet bonnet (3). Position outlet bonnet (3) on

the core assembly and install bolts (1). Tighten

the bolts finger tight.

5. Tighten bolts (8), (1) and (11) to a torque of

47 N·m (35 lb ft).

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

24

KENR6232

Disassembly and Assembly Section

6. Fill the cooling system. Refer to Operation and

Maintenance Manual, “Cooling System Coolant

- Change”.

2. Remove the fasteners and remove the assembly

of the suction pipe (2). Remove the O-ring seal

from the tube assembly.

7. Check the level of the engine lubricating oil. Refer

to Operation and Maintenance Manual, “Engine

Oil Level - Check”.

3. Remove bolts (5) and remove engine oil pump (1)

from the cylinder block.

4. If necessary, remove bolts (4) and remove

underframe assembly (3).

i02554736

Engine Oil Pump - Remove

i02554733

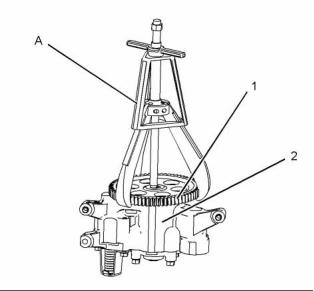

Engine Oil Pump - Disassemble

Removal Procedure

Start By:

Disassembly Procedure

a. Remove the engine oil pan. Refer to Disassembly

and Assembly, “Engine Oil Pan - Remove and

Install”.

Table 14

Required Tools

Tool

Part Number

Part Description

Qty

NOTICE

A

-

Puller (Three Leg)

1

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Start By:

a. Remove the engine oil pump. Refer to

Disassembly and Assembly, “Engine Oil Pump -

Remove”.

Dispose of all fluids according to local regulations and

mandates.

NOTICE

Keep all parts clean from contaminants.

NOTICE

Contaminants may cause rapid wear and shortened

component life.

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

g01077736

Illustration 38

Typical example

1. Remove the fasteners and remove tube assembly

(6). Remove the O-ring seal from the tube

assembly.

g01001918

Illustration 39

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

25

Disassembly and Assembly Section

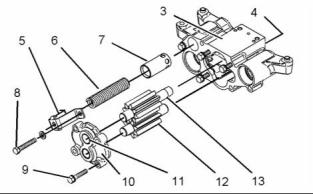

1. Remove the bolt that holds drive gear (1) to the

shaft of engine oil pump (2). Use Tooling (A) to

remove the drive gear from the shaft. Remove the

key from the shaft.

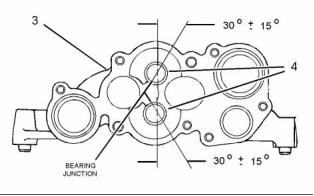

g01103246

Illustration 41

1. Use a press and a suitable tool to install sleeve

bearings (4) in pump body (3). The bearing joint

should be 30 ± 15 degrees from the center line of

the two bearing bores. Install the sleeve bearings

so the sleeve bearings are even with the outside

of the pump body.

g01101672

Illustration 40

Personal injury can result from parts and/or cov-

ers under spring pressure.

Spring force will be released when covers are re-

moved.

Be prepared to hold spring loaded covers as the

bolts are loosened.

2. Remove bolts (8). Remove retainer (5), spring (6),

and relief plunger (7) from pump body (3).

3. Remove bolts (9) and cover (10).

g01101732

4. Remove idler gear (12) and drive gear (13) from

Illustration 42

the pump body.

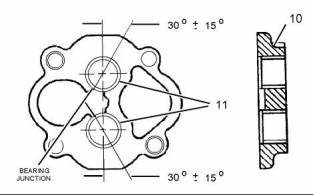

2. Use a press and a suitable tool to install sleeve

bearings (11) in cover (10). The bearing joint

should be 30 ± 15 degrees from the center line of

the two bearing bores. Install the sleeve bearings

so the sleeve bearings are even with the outside

of the cover.

5. Use a suitable tool to remove sleeve bearings (4)

from the pump body.

6. Use a suitable tool to remove sleeve bearings (11)

from the cover.

i02554732

Engine Oil Pump - Assemble

Assembly Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

g01101672

Illustration 43

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

26

KENR6232

Disassembly and Assembly Section

i02554734

Engine Oil Pump - Install

Improper assembly of parts that are spring loaded

can cause bodily injury.

To prevent possible injury, follow the established

assembly procedure and wear protective equip-

ment.

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

3. Lubricate the idler gear and the drive gear with

clean engine oil. Lubricate sleeve bearings (4)

with clean engine oil. Install idler gear (12) and

drive gear (13) in pump body (3).

Contaminants may cause rapid wear and shortened

component life.

4. Lubricate sleeve bearings (11) with clean engine

oil. Install cover (10). Install bolts (9).

Note: The engine oil pump must turn freely after

assembly. Turn the engine oil pump by hand.

Reposition cover (10) if the engine oil pump does not

turn freely.

5. Install relief plunger (7), spring (6), retainer (5),

and bolts (8).

6. Install the key on the shaft.

g01077736

Illustration 45

Typical example

1. Position underframe assembly (3) on the cylinder

block. Install bolts (4). Tighten the bolts to a torque

of 47 N·m (35 lb ft).

2. Position engine oil pump (1) on the dowels in the

cylinder block. Install bolts (5). Tighten the bolts

to a torque of 47 N·m (35 lb ft).

Note: Ensure that the engine oil pump is seated on

the dowels before the bolts are tightened.

g01101743

Illustration 44

3. Install a new O-ring seal to tube assembly (6).

Lubricate the bore in the engine oil pump with

clean engine oil. Install tube assembly (6). Install

the bolts that secure the tube assembly. Tighten

the bolts to a torque of 47 N·m (35 lb ft).

7. Install drive gear (1) on the shaft of engine oil

pump (2). Install bolt (14). Tighten the bolt to a

torque of 55 N·m (41 lb ft).

End By:

4. Install a new O-ring seal to the assembly of

suction pipe (2). Lubricate the bore in the engine

oil pump with clean engine oil. Install the assembly

of suction pipe (2). Install the bolts and washers

that secure the tube assembly. Tighten the bolts

to a torque of 47 N·m (35 lb ft).

a. Install the engine oil pump. Refer to Disassembly

and Assembly, “Engine Oil Pump - Install”.

End By:

a. Install the engine oil pan. Refer to Disassembly

and Assembly, “Engine Oil Pan - Remove and

Install”.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

27

Disassembly and Assembly Section

i02554791

Water Pump - Remove

Removal Procedure

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to local regulations and

mandates.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Drain the coolant from the cooling system into

a suitable container for storage or for disposal.

Refer to Operation and Maintenance Manual,

“Cooling System Coolant - Change”.

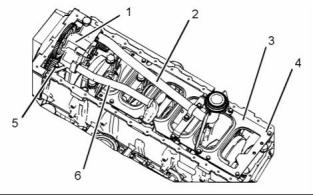

g01285782

Illustration 46

2. Remove bolts (2) from water temperature regulator

housing (1). Remove water temperature regulator

housing (1) and pipe (3) as a unit. Remove the

O-ring seals from the water temperature regulator

housing and the pipe.

3. Remove bolts (5). Remove water pump cover (4)

from water pump (8). Remove the O-ring seal from

the water pump cover.

4. Remove bolts (7). Remove oil cooler bonnet (6)

from the engine oil cooler. Remove the joint and

the O-ring seal from the oil cooler bonnet.

5. Remove the belt tightener. Refer to Disassembly

and Assembly, “Belt Tightener - Remove”.

6. Attach a suitable lifting device to water pump (8).

Support the weight of the water pump. The water

pump weighs approximately 18.3 kg (40 lb).

7. Remove bolts (9).

8. Use the lifting device in order to remove water

pump (8) from the front housing. Remove the

O-ring seal from the water pump.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

28

KENR6232

Disassembly and Assembly Section

i02554790

2. Use a suitable lifting device in order to position

water pump (8) on the front housing. The water

pump weighs approximately 18.3 kg (40 lb).

Water Pump - Install

3. Install bolts (9). Tighten the bolts to a torque of

47 N·m (35 lb ft).

Installation Procedure

4. Install the belt tightener. Refer to Disassembly and

Table 15

Assembly, “Belt Tightener - Install”.

Required Tools

5. Install a new O-ring seal on oil cooler bonnet (6).

Apply Tooling (A) to the O-ring seal. Position the

joint and install oil cooler bonnet (6) to the engine

oil cooler. Install bolts (7). Tighten the bolts to a

torque of 47 N·m (35 lb ft).

Tool

Part Number

Part Description

Qty

POWERPART

A

21820221

1

Rubber Grease

NOTICE

6. Install a new O-ring seal to water pump cover (4).

Position water pump cover (4) on water pump (8)

and install bolts (5). Tighten the bolts to a torque

of 47 N·m (35 lb ft).

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

7. Install new O-ring seals to pipe (3). Apply Tooling

(A) to the O-ring seals. Install the pipe in the

water temperature regulator housing (1). Install a

new O-ring seal to water temperature regulator

housing (1).

8. Insert pipe (3) into water pump cover (4). Install

the assembly of the water temperature regulator

housing and pipe as a unit. Install bolts (2).

Tighten the bolts to a torque of 47 N·m (35 lb ft).

9. Fill the cooling system. Refer to Operation and

Maintenance Manual, “Cooling System Coolant

- Change”.

i02554792

Water Temperature Regulator

Housing - Remove and Install

Removal Procedure

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to local regulations and

mandates.

g01285782

Illustration 47

1. Install a new O-ring seal to water pump (8).

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

29

Disassembly and Assembly Section

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Drain the coolant from the cooling system into

a suitable container for storage or for disposal.

Refer to Operation and Maintenance Manual,

“Cooling System Coolant - Change”.

g01282552

Illustration 49

4. Remove water temperature regulator housing (1)

from housing manifold (2). Remove O-ring seal (7)

and O-ring seal (6) from the housing manifold.

5. Remove water temperature regulators (8).

6. Remove lip seal (10).

7. Remove pipe (4) from the water temperature

regulator housing. Remove O-ring seals (9) from

pipe (4).

g01282550

Illustration 48

Typical example

8. If necessary, remove coolant temperature sensor

(5). Refer to Disassembly and Assembly, “Coolant

Temperature Sensor - Remove and Install”.

2. Slide the locking tab into the unlocked position and

disconnect the harness assembly from coolant

temperature sensor (5).

Installation Procedure

3. Remove bolts (3). Remove pipe (4), water

temperature regulator housing (1), and housing

manifold (2).

Table 16

Required Tools

Tool

Part Number

Part Description

Seal Installer

Qty

A

27610309

1

POWERPART

Rubber Grease

B

218200221

1

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

30

KENR6232

Disassembly and Assembly Section

5. Loosely install bolts (3) to water temperature

regulator housing (1) and housing manifold (2).

Position water temperature regulator housing (1)

and housing manifold (2) onto pipe (4). Tighten

the bolts to a torque of 47 N·m (35 lb ft).

6. If necessary, install coolant temperature sensor

(5). Refer to Disassembly and Assembly, “Coolant

Temperature Sensor - Remove and Install”.

7. Connect the harness assembly to coolant

temperature sensor (5). Slide the locking tab into

the locked position.

8. Fill the cooling system. Refer to Operation and

Maintenance Manual, “Cooling System Coolant

- Change”.

i02554737

Engine Support (Front) -

Remove and Install

g01282552

Illustration 50

1. Use Tooling (A) to install lip seals (10) into water

temperature regulator housing (1).

Removal Procedure

2. Install new O-ring seals (9) onto pipe (4). Apply

Tooling (B) to the O-ring seals. Install pipe (4) to

the water pump.

Table 17

Required Tools

3. Install O-ring seal (6) and O-ring seal (7) to

housing manifold (2).

Tool

Part Number

Part Description

Guide Stud

Qty

A

-

2

4. Install water temperature regulators (8) into the

(1/2 - 13 UNC by 6 inch)

water temperature regulator housing (1).

Start By:

a. Remove the assembly of the vibration damper

and the crankshaft pulley. Refer to Disassembly

and Assembly, “Vibration Damper and Pulley -

Remove and Install”.

1. Support the front of the engine.

g01282550

Illustration 51

Typical example

g01286145

Illustration 52

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

KENR6232

31

Disassembly and Assembly Section

2. Remove bolts (1) and install Tooling (A). Remove

End By:

the remaining bolts.

a. Install the assembly of the vibration damper

and the crankshaft pulley. Refer to Disassembly

and Assembly, “Vibration Damper and Pulley -

Remove and Install”.

3. Remove engine support (2) from the cylinder

block. The weight of engine support (2) is

approximately 33.5 kg (74 lb).

Installation Procedure

i02554746

Flywheel - Remove

Table 18

Required Tools

Tool

Part Number

Part Description

Guide Stud

Qty

Removal Procedure

A

-

2

(1/2 - 13 UNC by 6 inch)

Table 19

1. Support the front of the engine.

Required Tools

Part

Tool

Number

Part Description

Qty

Guide Stud

5/8 - 18 by 8 inch

A

-

2

Start By:

a. Remove the electric starting motor. Refer to

Disassembly and Assembly, “Electric Starting

Motor - Remove and Install”.

NOTICE

Keep all parts clean from contaminants.

g01286145

Illustration 53

Contaminants may cause rapid wear and shortened

component life.

2. Position engine support (2) on Tooling (A). The

weight of engine support (2) is approximately

33.5 kg (74 lb).

3. Install bolts (1) finger tight. Remove Tooling (A)

and install the remaining bolts.

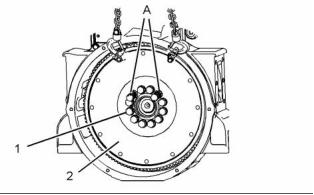

g01282130

Illustration 55

Typical example

1. Use a suitable tool to lock the flywheel. Loosen

bolts (1).

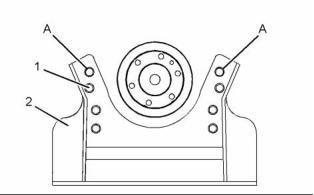

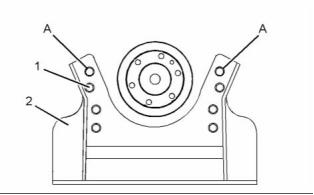

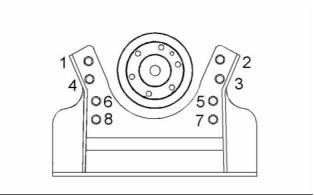

g01286401

Illustration 54

2. Attach a suitable lifting device to flywheel (1).

Support the weight of the flywheel. The weight of

flywheel (2) is approximately 130 kg (286 lb).

Tightening sequence

4. Install bolts (1). Tighten the bolts to a torque of

105 N·m (77 lb ft) in the order that is shown in

Illustration 54.

3. Remove two bolts (1). Install Tooling (A).

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

32

KENR6232

Disassembly and Assembly Section

4. Remove the remaining bolts (1). Use the lifting

device in order to remove flywheel (2).

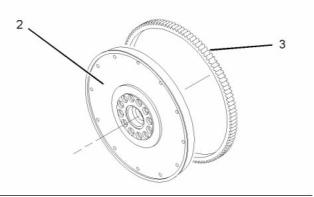

g01091705

Illustration 57

g01091705

Illustration 56

Typical example

Always wear protective gloves when handling

parts that have been heated.

5. Inspect flywheel (2) and ring gear (3) for wear or

damage. Replace any components that are worn

or damaged.

1. If the flywheel ring gear was removed, follow

Steps 1.a through 1.c in order to install a new ring

gear to the flywheel.

6. To remove the flywheel ring gear, follow Steps 6.a

and 6.b.

a. Identify the orientation of the teeth on the new

a. Place the flywheel assembly on a suitable

ring gear (3).

support.

Note: The chamfered side of the ring gear teeth must

face toward the starting motor when the flywheel is

installed. This will ensure the correct engagement of

the starting motor.

Note: Identify the orientation of the teeth on the

flywheel ring gear.

b. Use a hammer and a punch in order to remove

ring gear (3) from flywheel (2).

b. Heat flywheel ring gear (3) in an oven to a

maximum temperature of 316 °C (600 °F) prior

to installation.

i02554744

Flywheel - Install

Note: Do not use a torch to heat the ring gear.

c. Ensure that the orientation of ring gear (3) is

correct and quickly install the ring gear onto

flywheel (2).

Installation Procedure

2. Inspect the crankshaft rear seal for leaks. If there

are any oil leaks, replace the crankshaft rear seal.

Refer to Disassembly and Assembly, “Crankshaft

Rear Seal - Remove”.

Table 20

Required Tools

Tool

Part Number

Part Description

Qty

Guide Stud

A

-

2

5/8 - 18 by 8 inch

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6232

33

Disassembly and Assembly Section

Start By:<, /P>

a. Remove the flywheel. Refer to Disassembly and

Assembly, “Flywheel - Remove”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The crankshaft rear seal and the wear sleeve

must be replaced as a unit. Once the crankshaft

rear seal and the wear sleeve are separated, these

components can not be used again.

g01282130

Illustration 58

Typical example

3. Install a suitable lifting device to flywheel (1). The

weight of flywheel (2) is approximately 130 kg

(287 lb).

4. Install Tooling (A) on the crankshaft.

5. Use the lifting device in order to position flywheel

(1) onto Tooling (A).

6. Apply clean engine oil to the threads of bolts (1).

7. Install bolts (1). Remove Tooling (A). Install

remaining bolts (1).

8. Use a suitable tool to prevent the flywheel from

rotating. Tighten bolts (1) to a torque of 270 N·m

(200 lb ft).

9. Remove the lifting device from flywheel (1).

g01007851

Illustration 59

Typical example

10. Check the runout of the flywheel. Refer to

Systems Operations, Testing and Adjusting,

“Flywheel - Inspect”.

1. Use a 4 mm (0.158 inch) drill in order to make

three or more holes in wear sleeve (2).

End By:

2. Use Tooling (A) to remove the wear sleeve.

a. Install the electric starting motor. Refer to

Disassembly and Assembly, “Electric Starting

Motor - Remove and Install”.

3. Use a 4 mm (0.158 inch) drill in order to make

three or more holes in crankshaft rear seal (1).

i02554710

4. Use Tooling (A) to remove crankshaft rear seal (1).

Crankshaft Rear Seal - Remove

Removal Procedure

Table 21

Required Tools

Part

Tool

Number

Part Description

Qty

A

27610311

Slide Hammer Puller

1

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

34

KENR6232

Disassembly and Assembly Section

i02554709

Crankshaft Rear Seal - Install

1. Before installation of the crankshaft seal and the

wear sleeve, inspect the crankshaft for scratches.

Also, inspect the crankshaft for any distortion

on the surface that may lead to an out of round

condition. Use a polishing cloth in order to remove

any imperfections on the crankshaft.

Installation Procedure

2. Clean the outside diameter of the crankshaft and

Table 22

the inside diameter of the wear sleeve.

Required Tools

Part

3. Fasten Tooling (B) to the crankshaft with Tooling

(C).

Tool

B

Number

GE50008

GE50009

GE50014

GE50013

Part Description

Qty

1

Note: Install the crankshaft rear seal with the arrow

that shows the direction of crankshaft rotation toward

the rear of the engine.

Seal Locator

C

Bolt

3

D

Nut (Seal Installer)

Seal Installer

1

4. Position wear sleeve (2) and crankshaft rear seal

(1) on Tooling (B). Install Tooling (E) on Tooling

(B). Lubricate the face of the washer on Tooling

(D). Install Tooling (D) on Tooling (B).

E

1

NOTICE

Keep all parts clean from contaminants.

5. Tighten Tooling (D) until Tooling (E) contacts

Tooling (B).

Contaminants may cause rapid wear and shortened

component life.

6. Remove Tooling (D) and Tooling (E) from Tooling

(B).

Note: Do not lubricate the crankshaft seal or the wear

7. Remove Tooling (C) and Tooling (B) from the

sleeve. The crankshaft seal must be installed dry.

crankshaft.

8. Check the crankshaft rear seal and the wear

sleeve for the correct installation.

End By:

a. Install the flywheel. Refer to Disassembly and

Assembly, “Flywheel - Install”.

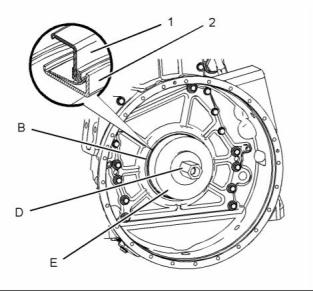

i02554749

Flywheel Housing - Remove

and Install

Removal Procedure

Table 23

g01007913

Required Tools

Illustration 60

Typical example

Tool

Part Number

Part Description

Guide Stud

Qty

Note: Do not use any type of lubricant during the

A

-

2

(3/8 - 16 x 4inch)

installation of the crankshaft seal and wear sleeve.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

KENR6232

35

Disassembly and Assembly Section

Start By:

3. Remove remaining bolts (2). Use the suitable

lifting device to remove the flywheel housing from

the cylinder block.

a. Remove the electric starting motor. Refer to

Disassembly and Assembly, “Electric Starting

Motor - Remove”.

Note: It is not necessary to remove the dowels in the

cylinder block that locate the flywheel housing.

b. Remove the crankshaft rear seal. Refer to

Disassembly and Assembly, “Crankshaft Rear

Seal - Remove”.

Installation Procedure

Table 24

c. Remove the engine oil pan. Refer to Disassembly

and Assembly, “Engine Oil Pan - Remove and

Install”.

Required Tools

Tool

A

Part Number

Part Description

Qty

2

Guide Stud

NOTICE

-

(3/8 - 16 x 4inch)

Sealant

Care must be taken to ensure that fluids are contained